Companies need to create agile and sustainable manufacturing processes that require streamlined processes and increased visibility into production plants and supply chains. Microsoft Dynamics 365 (D365) Supply Chain Management enables organizations to streamline production processes with improved shop floor visibility and improve throughput and quality.

Priority Based Planning

One challenge manufacturers face is when multiple orders for the same items land simultaneously and there isn't enough stock to meet demand. Which distribution center or store should orders be filled and in what order? What is most important and how should manufacturers prioritize? Although it is easy for one person to manually decide priorities in situations like this, manufacturers lack the automation to make these decisions.

master planning with Planning Optimization is changing the game for manufacturers. The priority-based scheduling feature can be used to set optimal replenishment based on priority, rather than just date. This enables companies to increase service levels, reduce on-hand inventory, and streamline their supply chains by prioritizing replenishment orders to ensure demand is met by level of urgency.

Planning priority is automatically calculated based on flexible settings that consider inventory levels for minimum, reorder point, maximum, and projected available inventory that includes planned receipts and distributions. This data can be used to compare the importance of any order across products and locations.

With priority-based planning, organizations gain the ability to:

- Calculate, manually edit, or set scheduling priorities by default.

- Control replenishment by setting reorder point parameters.

- Split and optimize distribution orders using planning ranges.

- Group of planned orders in the firm.

- Use customizable scheduling priority ranges.

- Apply planning priority capabilities to intercompany orders.

MES Integration

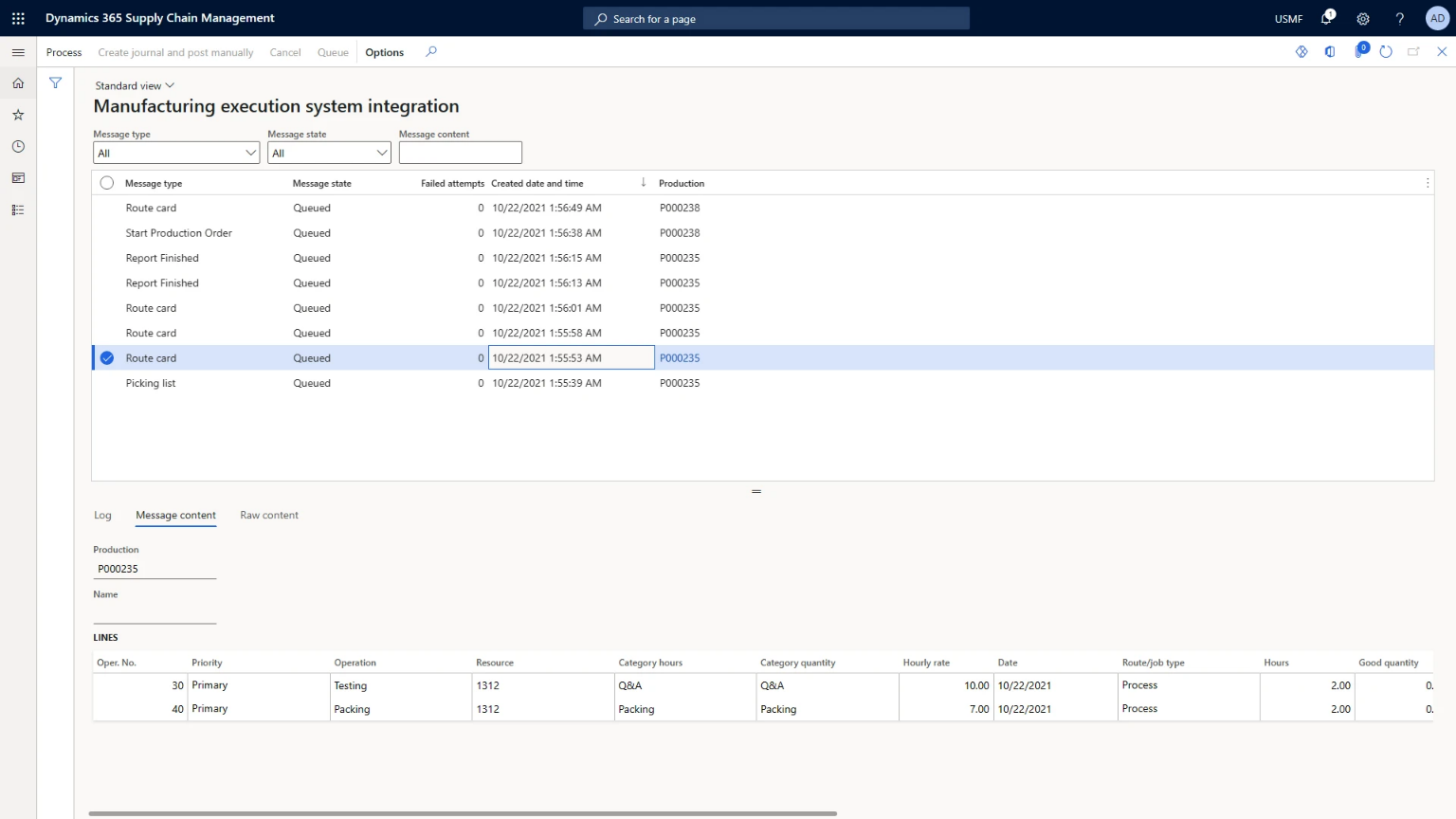

Manufacturers invest heavily in two layers of automation: production lines and equipment and enterprise resource planning (ERP) systems. One challenge manufacturers have faced when dealing with these two separate automation layers is how to keep data in sync as transactions occur across both. Fortunately, the Manufacturing Execution System (MES) resides between these two layers and manages the unique operational requirements of manufacturing.

Dynamics 365 Supply Chain Management MES integration provides the means to keep data and transactions in sync between both systems. Plus, it makes it faster and easier to integrate Dynamics 365 Supply Chain Management with common manufacturing execution systems.

By integrating a third-party MES solution with Dynamics 365 Supply Chain Management, data exchange is fully automated in near real time. This is important because it keeps data up-to-date in both systems and also eliminates the need for manual data entry (which is often error-prone).

With the introduction of MES integration, Dynamics 365 Supply Chain Management is reducing overall implementation and operating costs and helping manufacturers establish end-to-end visibility and control over the shop floor.

Next steps

If you are interested in learning more about optimizing production processes with D365, as well as maximizing the use of Microsoft Dynamics 365 for Finance and Supply Chain Management, do not hesitate to contact us.